If you are not employed in some type of mechanical or design field, chances are you have never heard of shock absorbing casters much less know what they are. If you are reading this, then you are probably at least minimally curious about them. So to get you started on learning about them, here is a brief intro.

What Are They?

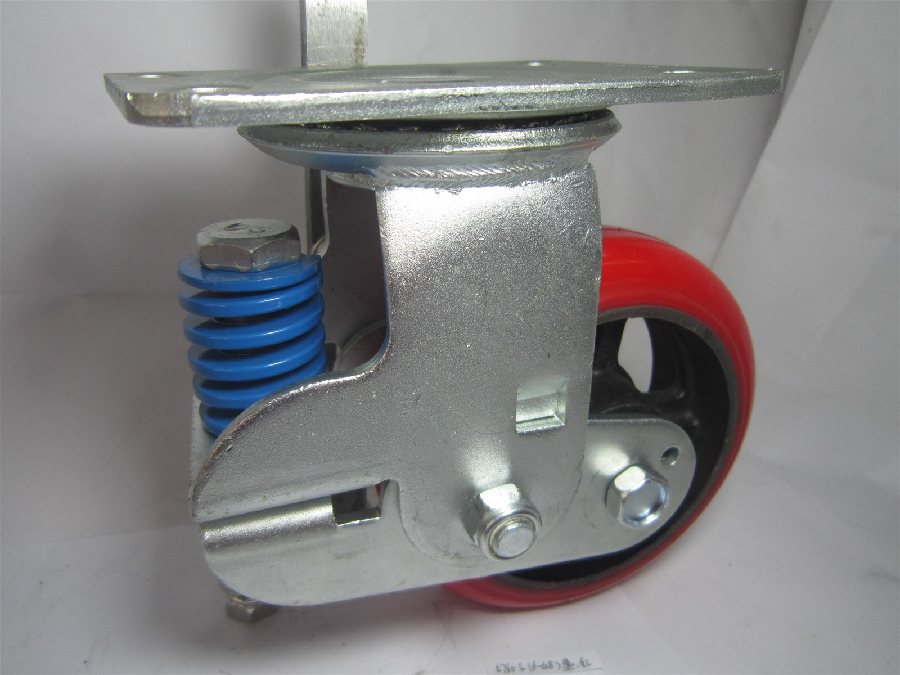

So to begin with, a caster is an assembly composed of a bracket and a wheel. If you saw a caster, you would immediately recognize it, though you would probably identify it as a wheel and not a caster. The difference between a caster and a regular wheel is the bracket: A caster has one, a wheel does not. For example, the little “wheels” on the legs of rolling chairs are actually casters, not wheels. Shock absorbing ones are specifically designed to withstand the vibrations and shock of movement and are usually spring loaded.

What Are Their Uses?

Casters are used for many purposes. As mentioned before, they are found on rolling chairs. They are also used for carts, hospital beds, assemblies and industrial equipment. The shock absorbing ones are used when noise reduction is a goal and/or when the equipment the casters are on is being used to transport fragile or delicate products.

What Are Their Benefits?

Besides reducing vibrations (and thus damage) and noise, casters designed with shock absorption come with other benefits. One benefit is that equipment using this kind of caster can be more easily rolled over floors that are not smooth and level. The absorption of shock also lessens the amount of damage incurred by the floors.

Casters are a useful invention that, while not the first thing to come to mind when thinking about modern innovation, make life easier. Shock absorbing ones are especially beneficial because of their shock, damage and noise reducing properties.