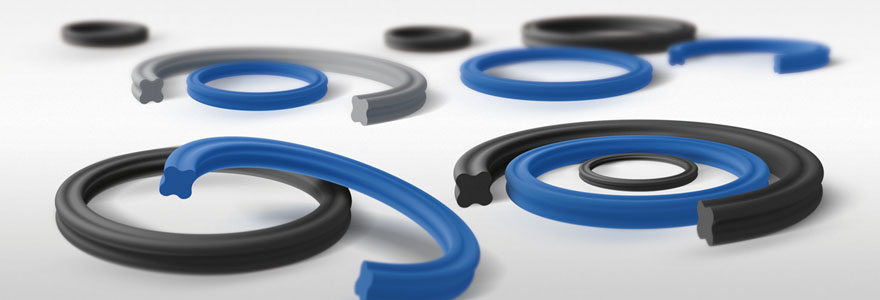

For the longest time, you might have been using O-rings to prevent contaminants from entering your system. At the same time, the frequent monthly sealant replacement makes you wonder if there’s another alternative, doesn’t it? As such, the unique Quad rings present themselves with the four-lobed structure to help your application accomplish every task smoothly.

If you want to prolong your applications’ life and dispose of replacement worries in one stroke, the solution you seek lies with the groundbreaking sealant variety. Even the high living cost in your neighborhood will strike a budget balance chord with the quad ring supply in Ballwin, MO.

How Are Quad-Rings Different From O-Rings?

Now that you are willing to shift from traditional to state-of-the-art sealant, it’s time to know all about your upgrade!

O-Rings

The O-rings are your malleable doughnut-shaped structure that adjusts around the machinery cross-section for rotation safety.

Usually constructed out of elastic polymers, the O-rings are your sealants that restrict the liquid or gas flow from one compartment to another. The marvels of mechanical engineering ensure a safer working environment for you and your machinery. Additionally, they’re flexible enough to be molded out of different varieties like fluorosilicone, Buna-N, etc.

From engines to beer pint caskets, you can always find an O-ring to secure the machinery parts and lock in the pressure.

Quad Rings

Quad Rings or X-seals get their name because of their cross-sectional four-lobed structure, which prevents spinning failure in rotary applications. The architectural brilliance in the construction of the sealant helps with drastically reducing the frictional and rotational loss. And the best part is they come with compatibility in all the applications, including the O-rings grooves.

Meanwhile, even though they cost more than the standard O-rings, they can handle the friction between the machine parts with more extended efficiency.

What Makes Quad-Rings a Non-Negotiable Feature?

Every dynamic application needs a top-notch sealant to function through diverse processes. Meanwhile, if you’re living in Ballwin, MO, the humidity factors form a strong determinant of the sealant choice. As such, if the high moisture and rain block your applications’ smooth processing, the solution you seek lies with the groundbreaking sealant variety. Also, the Quad-rings provide:

Proper Lubrication

The presence of the structural depressions at both sides of the ring ensures stronger fixation with dedicated lubrication space. Besides, it allows friction reduction with a more significant sealing effect through lubrication retention.

Sealing Strength

The four-lobed design allows the ring to grab hold of the machinery surface. And the robust sealing through the structure provides your machinery a friction-free environment to function.

Superior Stability

Unlike the bunching and spinning in cheap sealants, the X-shaped pattern offers a firm grip over the mating surfaces. Additionally, the higher footprint makes way for lesser torsion and smoother operations.

Lasting Lifespan

Most of the sealant varieties lose their lives due to constant friction and functional deformation. The good news is – the mechanical engineering in the sealant arrests the crumbling and eventually aids in prolonging the lifespan.

Quad-rings are the most effective sealant that you can provide to your machinery. It proves to be all the more beneficial if the application operations are dynamic in nature. You will not only prevent fluid leakage but also stop the expenditure wastage when you choose the multi-lobed quad ring supply in Ballwin, MO. So, it’s time you care for your machinery beyond lubrication supply and dust protection!