When you think of lasers, you probably feel overwhelmed with memories from your childhood when holidays were spent playing laser tag with your friends or pretending to be a sniper while your little sister watched cartoons. Perhaps your favourite memories were made watching your cat chase the tiny red dot along the floor, all while they never understood why they couldn’t catch it. Whatever your childhood laser memories are, the common thread is that they brought you a lot of joy and perhaps even got you into trouble a few times, but hey, what are children to do, right? Well, if you are a laser lover, the fun doesn’t have to stop when you turn sixteen. Many industries have adopted the use of lasers in many regards, from experimental physics, engineering and on production lines for various products. Laser alignment tools help workers gain precision and accuracy that older machinery may not have to offer. In addition, if you have a vivid imagination, laser alignment tools are the perfect accessory to make your vision come to life. Of course, always operate machinery appropriately and professionally, but enjoy your work at the same time.

Why You Should Use Laser Alignment

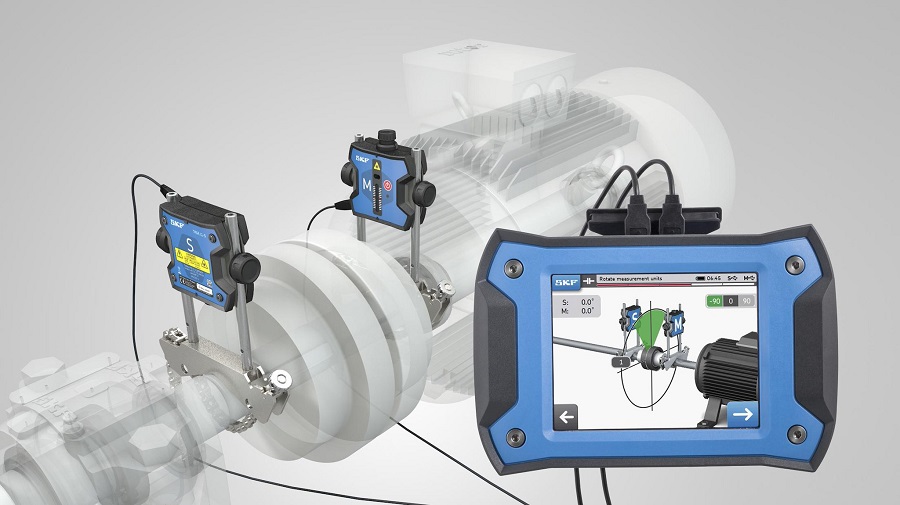

Like most people, you probably have no idea what laser alignment is and what it is used for. Don’t feel embarrassed, though; you are not alone. Simply put, a laser alignment tool is necessary to rectify the misalignment of shafts so that a machine’s motor can run efficiently. Misalignment significantly reduces the lifespan of machinery as damage is incurred from excessive vibrations and other factors and results in more frequent repairs, spare part orders and ultimately, poor product production. Of course, there are many products on the market for alignment, and many companies have their own course for collaboration, but, unfortunately, very few of the older products can compare to the precision of a laser alignment tool. So, why should you invest in laser alignment?

- Accuracy – laser alignment is alot faster and more accurate than dial-up gauges or straight edge methods. Accuracy means fewer breakdowns and less downtime.

- Easy to use – compared to dial-up gauges that often require extensive experience, laser alignment is simple to set up, and readings are easy to understand.

- Fast results and easy report feedback – laser alignment allows for instant reports from the instrument so you can compile documentation for the ‘before’ and ‘after’ of misaligned machinery. This is a necessity for businesses that have internal auditing.

- Save money – laser alignment gives you fast results and undeniable precision, so you are saving money due to fewer repairs and faster production.

- Consistency – laser alignment will yield the same results regardless of who is operating the machine. There is no temperament for change.

- Reduced energy consumption – a misaligned machine will use more energy to yield the same results as an aligned machine. The long-term benefits of reduced energy consumption are not only good for your bills but also good for the environment.

As you can see, there are many reasons to invest in laser alignment for your company. Eliminate slow production and faulty machinery and rely on the precision of laser alignment tools for incomparable results.

Sustainability

It can be extremely frustrating when you have to re-calibrate your machinery every few days because they continue to give you problems. Unfortunately, there are only so many times you can tweak a machine before it becomes a liability to production. Sustainability is vital in a production line to ensure a steady flow and consistent turnover, but the industry relies significantly on the equipment to do the heavy lifting. Misalignment is an inevitable occurrence in heavily used equipment, but you can significantly improve function and productivity with the correct alignment tools. The accuracy and precision of a laser alignment tool allow you to rectify issues as quickly as possible, so your production line doesn’t experience significant loss.

Sure, there is still a place for dial-up gages, and many businesses may prefer it over alternative alignment tools. But, if you are looking for the next level of ease, precision and definitive results, you need a laser alignment tool from Benchmark PDM. Browse our website to learn more about our services, or contact us today to find out how we can help you.