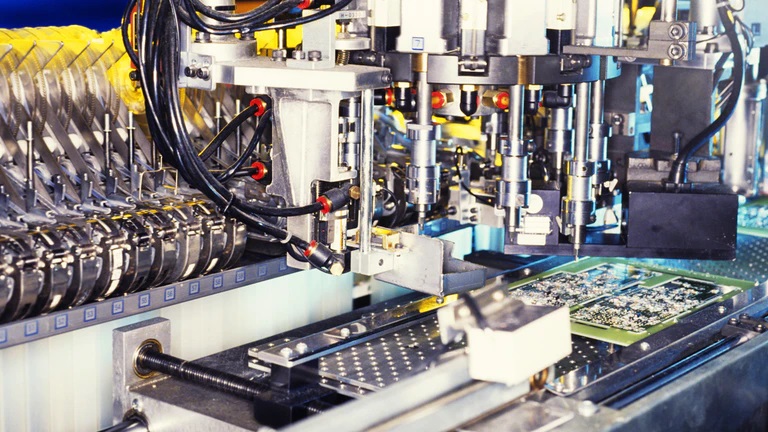

When working within any industry, the cost of materials must be worked into the cost of the services provided. Otherwise, you are losing money and not doing yourself any favors. While this is a fair pricing system, increased prices due to material usage can be offputting to customers and clients. Let’s take a look at how to reduce PCB assembly costs without sacrificing the quality of your work or components.

Optimize Everything

The single most important thing you can do in reducing your overall cost is to optimize your planning and design. You can optimize your bare PCB design to prevent errors in assembly and reduce your overall costs and overhead. You can get assistance from some manufacturers for free through a design-for-manufacturing test to help with the optimization process. This can greatly help to make the electronic PCB assembly go a lot more smoothly and cut down on waste and excessive cost.

Use Manufacturer Sources

Manufacturer sources are going to be some of the most valuable tools you can access. Sourcing components for out-of-date or obsolete items can be a pain and take up a lot of time. Fortunately, you can use manufacturer sources for strategic sourcing and can help you access these harder to find components at affordable rates.

Deliver a Full Bill of Parts

A bill of parts breaks down for the client and your record exactly what parts went into a repair from your electronic assembly services company and how much each part costs, making it easier for them to understand why they are being charged what they are. The name of the part, quantity, price, and all other relevant information to reduce the argument surrounding the price and cost of all of the materials involved with your electronic assembly services.

Inspections and Error Reductions

When working on an electronic PCB assembly, you have to inspect your work. The last thing you want is for everything to be great and sent off properly then an issue arises, wasting parts, and increasing your cost. Inspecting your work and looking for errors can cut down on how much you spend and how much time each job takes, saving you a lot in the long run. Plus, your clients will be much more satisfied if you do not have to have the item returned for more work.

Get Professional Help

HELTRONICS, a leading electronic PCB assembly entity providing a wide range of services, offers professional help and expert level repairs and assemblies. One of the most surefire ways to prevent issues with your assemblies and processing is to get professional help. The team at HELTRONICS is experienced and ready to take on whatever you may throw at them, allowing you to confidently place any job, big or small, in their hands. With HELTRONICS, you always know what you are going to get: quality, honest repairs. Reach out today through the contact form on the website for more information about assemblies, repairs, and quotes. With HELTRONICS, you are in good hands.