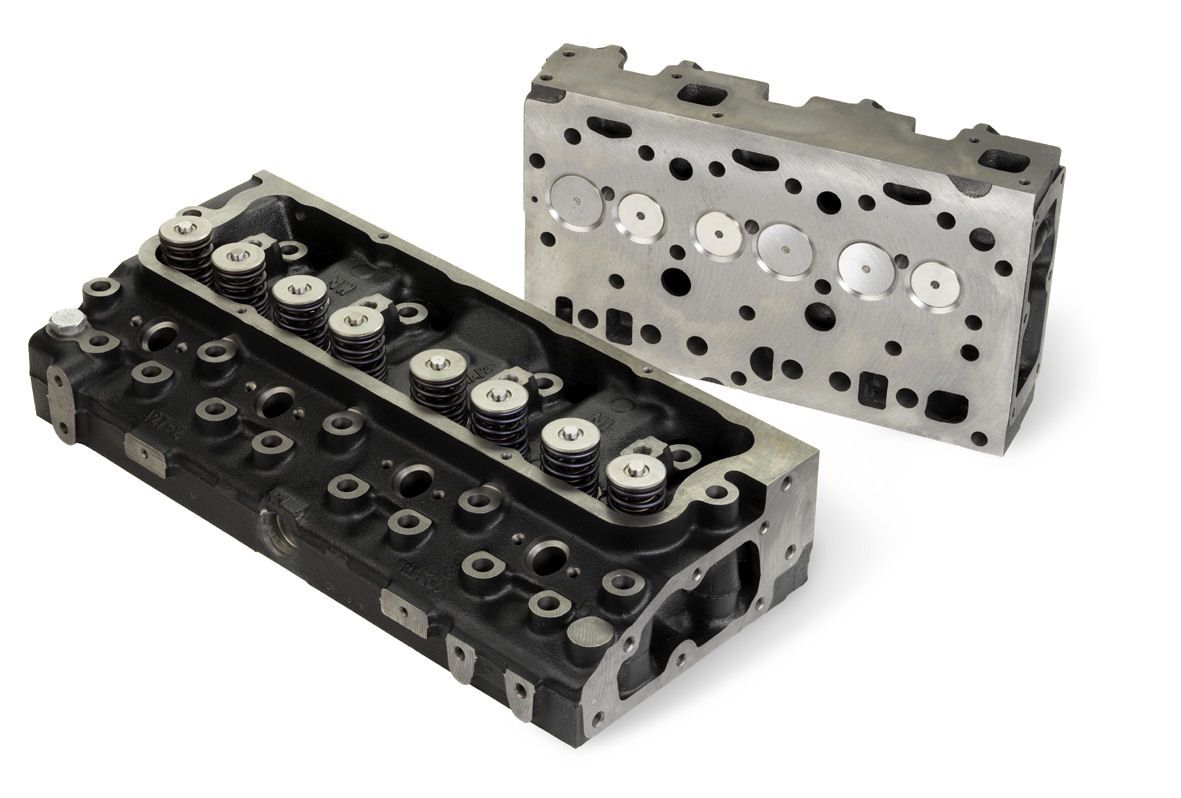

A cylinder head is one of the essential parts of an engine. It plays a vital role in ensuring your engine performs at its best by controlling torque, emissions, cooling, and acoustics.

There are a variety of performance cylinder heads on the market, and choosing the right ones for your application is essential. Port sizing and valve angle are just two of the factors that need to be taken into account.

Combustion Chamber

The combustion chamber is a critical part of the engine. It compresses the air-fuel mixture and ignites it to generate the power needed for your vehicle.

To achieve this, the cylinder head has to hold the compressed air/fuel mixture while allowing fresh air flow to enter and exit. It also accommodates the intake and exhaust valves, spark plug, and ignition system.

The cylinder head’s shape affects the efficiency of fuel compression, throttle response, and thermal efficiency. A good cylinder heads Victoria TX design can increase power output by increasing the compression ratio.

Intake Valve

Cylinder heads are one of the most critical components in your engine. They’re a machine’s most highly loaded parts, requiring a solid design to withstand tremendous pressures and temperatures.

They contain passages and tracks for air and fuel to flow in, out, and through the valves. They also carry ducts for the circulation of coolant.

A typical cylinder head features four intake and four exhaust ports, each matching up to an intake or exhaust valve. The shape and size of the ports is a basic spec because it affects torque and horsepower.

The port shape, size, and location can influence how much air the head can flow and how well it cools. Many head companies will include a port flow number to describe how much air it can cruise at different lifts.

Exhaust Valve

Cylinder heads are an essential part of your engine. They contain more moving details than anywhere else in the machine, so they must be solid and tough to withstand high pressures and temperatures.

When a fuel and air mixture is ignited in the cylinder, the exhaust gasses are sent out of the engine through an exhaust valve. The exhaust valve is larger than the intake valve, which ensures that all of the spent gases are ejected before new fresh air is introduced into the cylinder.

Exhaust valves are typically made from metals that can withstand higher temperatures than those used for the intake valves. They can be made from nichrome, tungsten steel, or cobalt-chromium alloys.

Valve Angle

The valve angle relative to the cylinder bore is critical in flow dynamics. A valve positioned too far upstream will reduce flow, while a small-to-medium valve angle improves the engine’s performance.

It uses 23 degrees for its small block but offers dozens of alternate valve angles starting at 18 degrees and going as high as 9 degrees for pure competition engines.

Many modern applications have a three-angle valve job consisting of a 45-degree seat and a top and bottom cut that’s 30 degrees and 60 degrees, respectively.

This creates less airflow disturbance, which is suitable for both intake and exhaust. This also helps smooth out airflow for better throttle response and power.

Valve Length

Cylinder Heads are a vital part of engine performance. Their shape, material selection, and preparation can significantly affect engine airflow, mixture quality, and speed.

A critical component of cylinder heads is the valve length. The longer the valve, the more potential there is for power development.

A long valve also allows for increased duration of the intake lobe design allowing more air charge to fill the cylinder for maximum power. This is especially critical at high RPM when a large amount of the air/fuel charge is needed to make power.

Another factor affecting engine performance is the timing of IVC closure. Opening the IVC too early limits the cylinder charge and decreases power and economy.