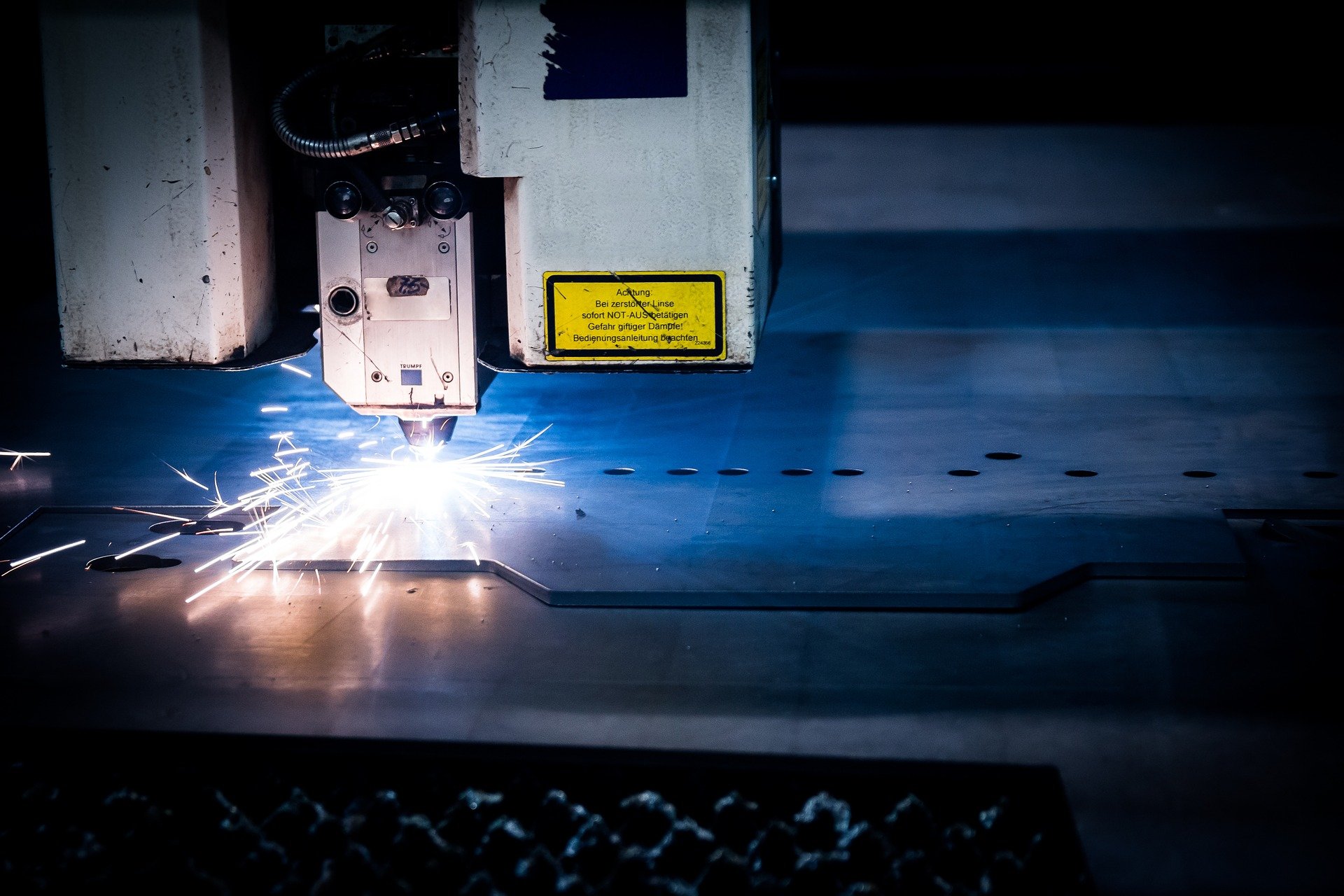

Business owners need reliable cutting tools that do not require extra steps. Laser cutters are more efficient products, and the business owner could decrease costs as well as extra steps. They can produce parts in a short time and build their inventory of products.

Ideal for Projects of All Sizes

Laser cutting perth tools are great for projects of any size, and the business can complete a multitude of projects with them. In comparison, traditional tools for laser cutting perth limit what the business can do and do not promote growth in the organization. By switching to laser cutters, the company could accommodate a larger client base and incorporate more complex projects into its roster. They can also expand into new markets and become far more profitable. Businesses can discover more about the cutting tools by visiting Boss Laser on YouTube now.

Better Precision and Accuracy

laser cutting brisbane guarantee precision and accuracy, and the business won’t have to worry about damaged materials or the expense of recuts. Workers enter the information about each project into the database, and the laser cutter does everything else for them. It is a speedy process, and the company could complete far more projects at an accelerated speed. This is highly beneficial for all businesses and gives them more of an edge over their competitors.

Uses Less Energy Than Standard Tools

The cutting tools do not use as much energy as traditional cutting tools, and the business owner could see major changes in their overhead costs. By saving more energy, the company has more capital to invest into new ventures, and they can get more out of their investments. Laser cutters do not draw power if they are not operational, and they do not use as much energy as other tools when they are used.

Doesn’t Make A Lot of Noise

Unlike many saws, the laser cutting tools will not cause excessive noise in the workplace. This could help employers decrease the risk of hearing loss for their workers, and they could provide a safer environment overall for their workers. When the laser starts, it doesn’t produce noise, and it will keep the workplace quieter. By replacing traditional cutting tools with the lasers, the business takes the necessary steps to protect their workers and create a better workplace.

Doesn’t Require Extra Steps After the Cut

With all traditional cutting tools, the worker will have to clean up the materials and may have to sand them to create smooth edges. Laser cutters do not produce jagged edges, and they do not require extra clean-up after. The workers can move the materials to the next step of the process without extra tasks and save time.

Business owners want precise cutting tools that do not present any risks to their workers, and the tools must complete the project faster. Speed is vital for business owners that create their own products, and they must produce a vast inventory in record time. Business owners can learn more about getting the tools by contacting a supplier now.